Discover What Makes Dry Ice Blasting Different

At Frostworks, we specialise in providing top-quality dry ice blasting services tailored to meet a variety of needs. Our experienced team is committed to delivering effective and environmentally friendly cleaning solutions, ensuring that your equipment and surfaces are maintained to the highest standards. Join us on this journey to understand the versatility and effectiveness of dry ice blasting in various applications, and see how it can make a positive impact on your operations.

Our Dry Ice Blasting Machines’ Stats

A Tailored Solution.

At Frostworks, we’ve equipped ourselves with two of the industry’s top dry ice blasters: the Dry Ice Energy Vario Champ and the ICS IC310S. The Vario Champ is a versatile little powerhouse, allowing us to adjust pressure from 2 to 10 bar and control the dry ice consumption rate between 10 to 50 kg per hour. This flexibility makes it perfect for the more delicate jobs, ensuring we have the precision and power to tackle any surface. Meanwhile, our IC310S is designed for high-impact cleaning, with a maximum pressure of 16 bar and a robust dry ice consumption rate of up to 100 kg per hour. This machine excels in demanding industrial environments where fast, efficient cleaning is critical. Together, these machines allow us to offer flexible, powerful, and eco-friendly cleaning solutions tailored to meet each client’s unique needs.

The Dry Ice Blasting Setup

Blasting Power and CFM: High CFM (Cubic Feet per Minute) airflow is crucial for dry ice blasting, as it ensures the efficient delivery of dry ice pellets, maximising cleaning power and effectiveness. A powerful air compressor propels the pellets at high speeds, allowing for thorough and efficient removal of contaminants.

Air Quality: Maintaining high air quality is essential to prevent moisture from interfering with the cleaning process. At Frostworks, we utilise a 4-stage filtration system with a Nano desiccant dryer to ensure that clean, dry air is delivered during blasting, enhancing effectiveness and protecting equipment integrity.

Mobile: Frostworks offers both electric and diesel air compressors for our mobile dry ice blasting services, providing effective cleaning solutions at various job sites. Our mobile setup ensures quick response times and minimal disruption, bringing the advantages of dry ice blasting directly to you.

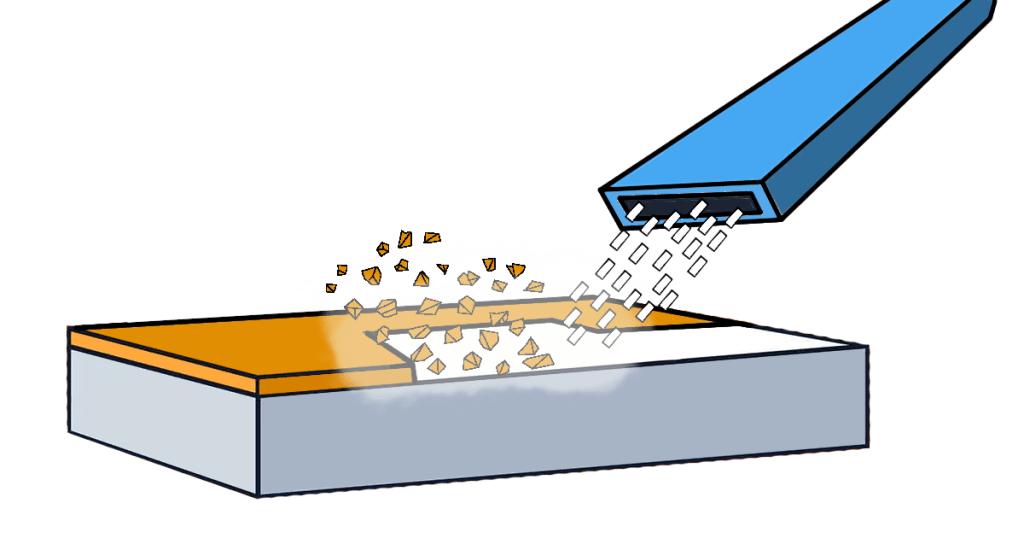

Cleaning in Three Steps

Impact: The process begins with dry ice pellets being accelerated at high speeds by a powerful air compressor. When these pellets collide with the surface being cleaned, they create a significant impact force that dislodges contaminants, dirt, and debris effectively.

Thermal Shock: As the dry ice pellets strike the surface, they rapidly cool it. This sudden temperature drop causes thermal shock, leading to the expansion and contraction of contaminants and surfaces. This effect further loosens the particles, making them easier to remove.

Sublimation: Finally, the dry ice undergoes sublimation, transitioning directly from a solid to a gas without leaving any residue behind. This means that once the dry ice pellets have done their job, they simply disappear into the atmosphere, ensuring a clean and eco-friendly process without secondary waste.